Hazardous Area Classification

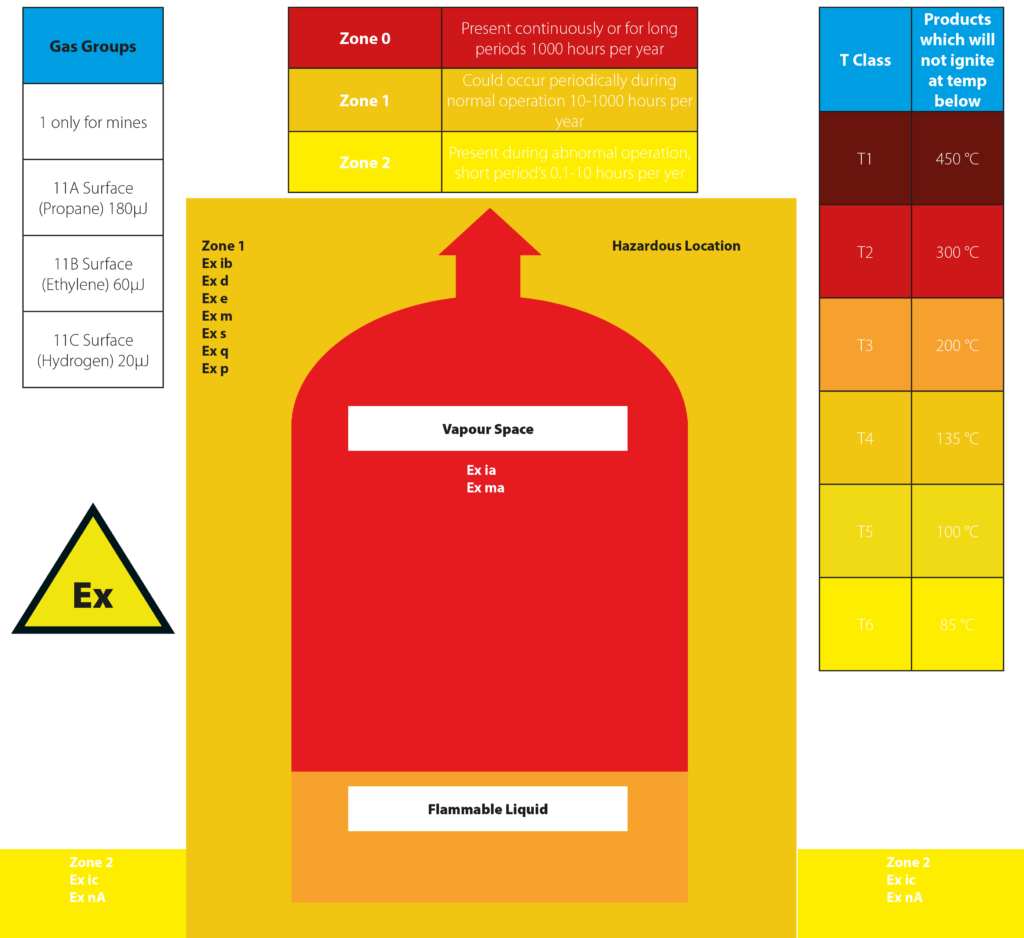

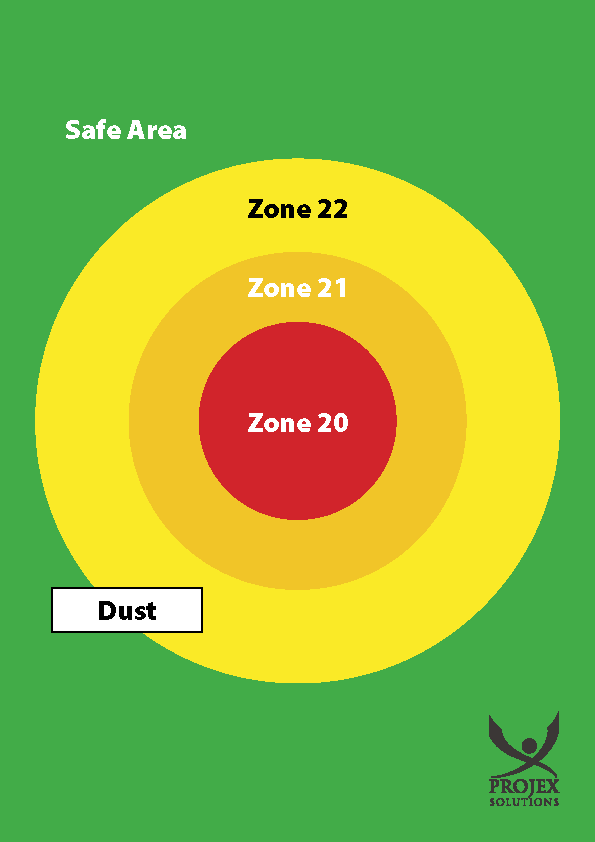

The Hazardous Area Classification concept applies to both combustible gases and vapours, mists, and sprays of combustible liquids, explosives, and combustible dusts. This concept has been in use for many years. It is essentially a systematic method of sub-dividing, into three dimensions, an industrial plant into zones of different categories according to the probability of occurrence of explosive atmospheres. The ultimate objective of this exercise is to keep the likelihood of accidental ignition of explosive atmospheres at a minimum throughout the plant.

There are a variety of advantages to delivering a HAC such as:

- Compliance to the relevant safety regulations

- Safety of Personnel and the workplace

- Reduced risk of fires or explosions.

- Possible cost savings if non-hazardous areas were incorrectly classified as hazardous.

- Electrical/electronic equipment can be specified safely and correctly.

We have many years of expertise and the capabilities required to conduct accurate and specified area classifications for hazardous areas within any process facility.

Compliance to the relevant safety regulations

A HAC ensures that your business is complying to the relevant standards associated with the Health and Safety Executive, failure to do this can result in penalties.

Safety of Personnel and the workplace

A HAC will help to protect staff and business facilities, by properly determining which zones offer safety and which zones are hazardous to workers and facilities. By determining these zones precautionary safety measures can be put in place for protection.

Reduced risk of fires or explosions

There is a reduced risk of fires and explosions, the zones indicate which areas need preventative measures put in place.

Possible cost savings if non-hazardous areas were incorrectly classified as hazardous

You may be taking preventive measures in areas that pose no risk to the business or staff, which can cause an unnecessary cost.

Electrical/electronic equipment can be specified safely and correctly.

Certain zones in a hazardous area require special electrical equipment, this equipment is designed to be safe to operate in hazardous areas.

Hazardous Area Classification – Standards

The most used standard in the UK for determining area extent and classification is:

- BS EN 60079-10-1:2015 – Part 10-1: Classification of areas – Explosive gas atmospheres

- BS EN 60079-10-2:2015, Explosive Atmospheres, Part 10-2: Classification of areas – Explosive Dust Atmospheres

Other sources/guidelines include:

- Energy Institute, Model Code of Safe Practice Part 15, Area Classification for Installations Handling Flammable Fluids, 4th Edition, 2015 (EI15)

- HSG103 – Safe Handling of Combustible and Dusts, 2003

- HSG176 Storage of Flammable Liquids in Tanks, 2nd Edition, 2015.

- HSG51 Storage of Flammable Liquids in Containers, 3rd Edition, 2015

- Area classification code for petroleum installation, 2002

- Institution of Gas Engineers Safety Recommendations SR25, 2001

Information contained on this page was sourced from the Health and Safety Executive, you can find out more here.